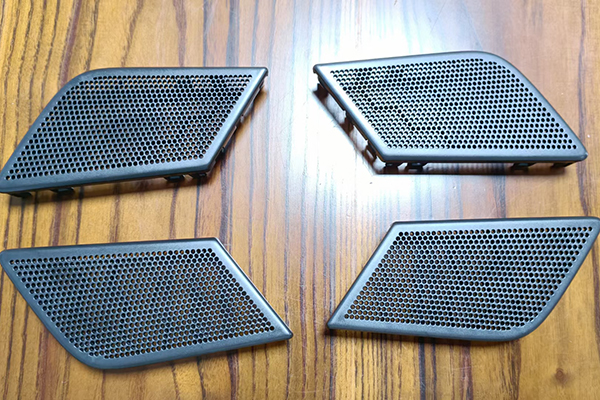

Slide Wear Plate

Brand Name:Hamsan

Mold Base:N/A

Mold Material:NAK80

Tolerance:+/-0.002mm

Shaping Mode:Plastic Injection Mould

Design Software:AutoCAD;NX;ProE

Packaging Details:Inner plastic bags+Wooden cases

Delivery Time:6 days manufacturing lead time

Products Details

Hamsan Tooling has been manufacturing mold components and accessories since 2004. HST Mold prides itself on its in-house design and fabrication. We employ highly skilled professional operators to operate our drill presses, CNC machines, EDM machines, proprietary mirror EDM machines and die polishers. With rich experience in mold parts processing, aiming at:

facilitate processes

reduce manufacturing timelines and costs

improve performance

Tolerance: +- 0.01mm

Processing cycle: 28 working days for a whole set of mold components, and Mold parts processing within 7 working days

Polishing: According to your request

Project Management:

Product DFM ⇒ Mold Design ⇒ Material Preparation ⇒ CNC Machining ⇒ EDM Machining ⇒ Grinding and Drilling Machining ⇒Wire Cutting ⇒ Polishing ⇒ Mold Fitting⇒ Mold Trail ⇒ Sample Inspection ⇒ Sample Approved ⇒ Mass Production ⇒ Mold(Product) Packing ⇒ Mold Delivery ⇒ After Sale Service

Our advantages:

1. Whole set mold components solution, which means, we could help you process all components on a mold, such as a mold base, mold core, sliders, standard parts...etc

2. Day shift and night shift.

3. 15 years of experience in the mold industry. We have rich experience in Experience of cooperating with mold factory

4. 30-set CNC machine Can handle more than 10 sets of mold accessories at the same time every month.

5. A 5-axis CNC machine can handle big mold sliders and mold bases.

Look forward to hearing your inquiry.

Tag: Mold Slider Components, Slider Jaw, Angle Pin, Slider Holder, Slide Insert, Slide Gib, Wear Plate, Slide Sub-insert

facilitate processes

reduce manufacturing timelines and costs

improve performance

Tolerance: +- 0.01mm

Processing cycle: 28 working days for a whole set of mold components, and Mold parts processing within 7 working days

Polishing: According to your request

Project Management:

Product DFM ⇒ Mold Design ⇒ Material Preparation ⇒ CNC Machining ⇒ EDM Machining ⇒ Grinding and Drilling Machining ⇒Wire Cutting ⇒ Polishing ⇒ Mold Fitting⇒ Mold Trail ⇒ Sample Inspection ⇒ Sample Approved ⇒ Mass Production ⇒ Mold(Product) Packing ⇒ Mold Delivery ⇒ After Sale Service

Our advantages:

1. Whole set mold components solution, which means, we could help you process all components on a mold, such as a mold base, mold core, sliders, standard parts...etc

2. Day shift and night shift.

3. 15 years of experience in the mold industry. We have rich experience in Experience of cooperating with mold factory

4. 30-set CNC machine Can handle more than 10 sets of mold accessories at the same time every month.

5. A 5-axis CNC machine can handle big mold sliders and mold bases.

Look forward to hearing your inquiry.

Tag: Mold Slider Components, Slider Jaw, Angle Pin, Slider Holder, Slide Insert, Slide Gib, Wear Plate, Slide Sub-insert